The Ultimate Guide To 24hr Media

Table of ContentsA Biased View of 24hr MediaThe 24hr Media Ideas4 Simple Techniques For 24hr MediaThe Best Guide To 24hr MediaMore About 24hr Media

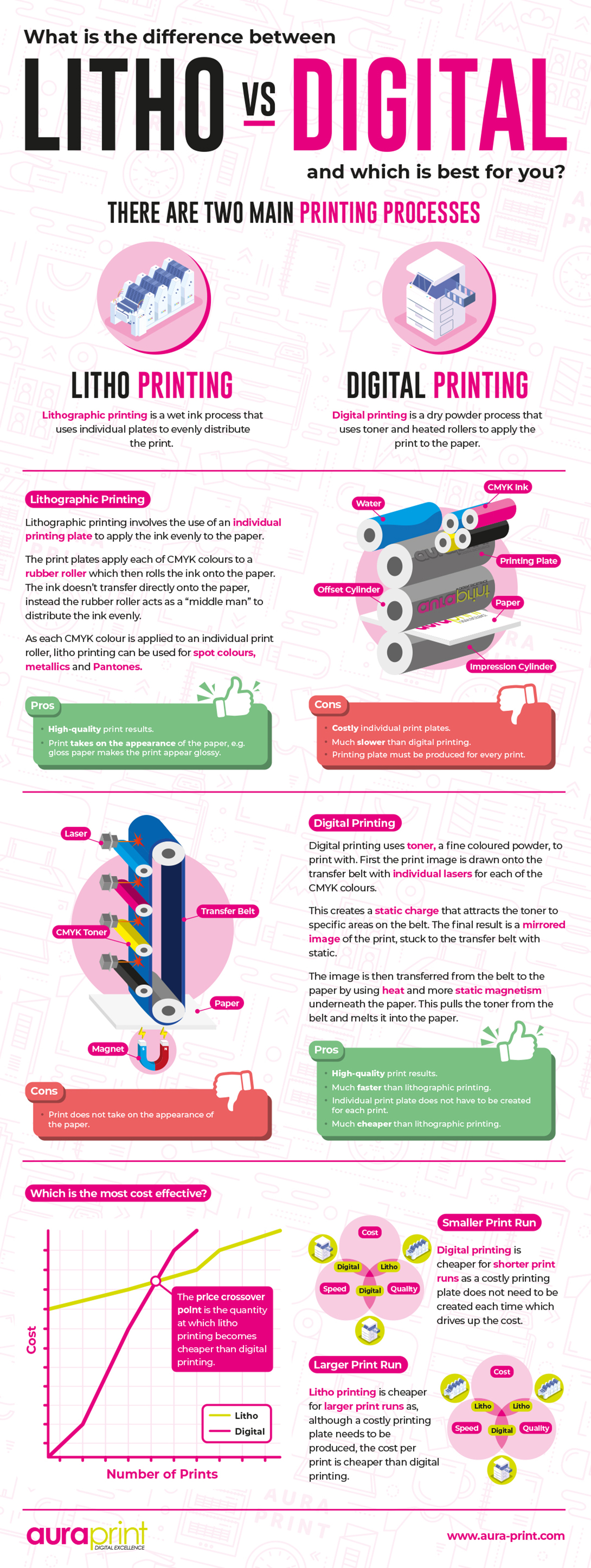

Improvements in print technology are altering the communications playing field when it pertains to top quality, price and sophisticated capabilities. Offset printing and electronic printing are the major procedures by which print work are taken on both using four-color printing approaches. Each choice has its benefits, supplying various methods to fulfill the demands of diverse manufacturing jobs.

Typically, this has been the most consistent method for exactly preserving color suits, making it suitable for print runs that only need static printing such as pre-printed kinds, sales brochures, leaflets, organization cards, and bulk postcard mailings. Nevertheless, as a result of the fixed nature of litho printing, it is not excellent for variable print items that will be mailed to private recipients such as declarations, letters, and personalized postcards.

24hr Media - The Facts

The most up to date improvements in print innovation are aiding to bring numerous of balanced out's advantages into the digital printing world truly altering the face of modern-day printing! There are some crucial differences between Offset Printing and Digital Printing (Digital Printing). This guide shows the advantages and drawbacks of each printing method. There is an undeniable and expanding number of advantages to utilizing the digital print procedure.

Today's electronic print devices is amongst the most cutting-edge on the market. Here are several of the biggest benefits of making use of digital printing: control the digital print area, with full-color printing completed in one process and effortlessly published directly from a print documents. Without an extensive set up process, the calibration time of a particular task is reduced, adding to quicker print time and overall shipment.

The inkjet printing procedure has actually aided to transform the industry along with the top quality and rate of the output. The current inkjet innovation can print on conventional balanced out supplies with dull, silk, and glossy surfaces. Top notch electronic print combined with software-managed shade monitoring techniques adds optimum worth to print items and makes manufacturing processes a lot more reputable than countered.

The Basic Principles Of 24hr Media

(http://www.askmap.net/location/7255850/south-africa/24%CA%B0%CA%B3media)

Precise amounts of ink and printer toner are used to prevent waste. Environmentally friendly and eco-friendly inks and printer toners are likewise offered for more sustainable printing. Digital print also removes the requirement to clean plates or blankets with damaging chemicals at the end of the printing process. As the top quality of digital print solutions boosts, the benefits become significantly evident and advantageous.

Variable data helps services reach their exact clients and audience with uniquely-created and individualized content. As technology improves, the high quality of digital printing has actually ended up being second-to-none, with greater detail, color match abilities and general precision. Without the requirement to clean plates or use excess ink, digital printing is also much less inefficient and typically extra eco-friendly.

("flexo"), entail numerous make-ready actions to transfer an initial picture to a substratum.

The Basic Principles Of 24hr Media

Digital printing, with less moving pieces, is extra nimble than countered in this regard.

It's a means to mix your product packaging and marketing approaches. Minimized set-up time conserves cash on the front end. And since these are not large bulk orders, smaller sized organizations can pay for to publish without browse around here having to fulfill the higher and a lot more expensive print limits of conventional printing. Digital printing assists secure your brand name against counterfeiting by incorporating overt and concealed solutions on your product packaging.

Make certain you collaborate with a printing and packaging companion who has the best accreditations. While eleventh-hour printing and personalization are a substantial benefit, electronic may not always be the ideal approach for you. As an example, offset printing has the advantage of cost-effectiveness with large print runs, particularly those with sophisticated ornamental impacts and specialty coverings.

Unknown Facts About 24hr Media

The positive plate, with its smooth surface, draws in oil-based inks and wards off water. In contrast, the negative plate, with its rough texture, absorbs water and drives away oil. Rubber rollers are after that made use of to move the picture from the plate to the corrugated surface.

Corrugated paper can sometimes confirm to be a challenging surface to publish on, yet Litho prints to a different surface and is after that laminated flooring to it, making it simple to publish high-quality photos. It can be extremely consistent, even for futures. Actually, the more you print, the cheaper the expenses come to be for Litho.

What Litho doesn't offer you is precisely what Digital does, customization. Expensive established up Longer turnaround No Variable Data Printing Smaller sized shade range, shades can be much less brilliant Digital printing is the process of printing electronic images straight onto the corrugated substratum utilizing a single-pass, direct-to-corrugate strategy.